Apple today announced a major acceleration of its work to expand recycled materials across its products, including a new 2025 target to use 100 percent recycled cobalt1 in all Apple-designed batteries. Additionally, by 2025, magnets in Apple devices will use entirely recycled rare earth elements, and all Apple-designed printed circuit boards will use 100 percent recycled tin soldering and 100 percent recycled gold plating.

From our partners:

In 2022, the company significantly expanded its use of key recycled metals, and now sources over two-thirds of all aluminum, nearly three-quarters of all rare earths, and more than 95 percent of all tungsten in Apple products from 100 percent recycled material. This rapid progress brings Apple closer to its aim to one day make all products with only recycled and renewable materials, and advances the company’s 2030 goal to make every product carbon neutral.

“Every day, Apple is innovating to make technology that enriches people’s lives, while protecting the planet we all share,” said Tim Cook, Apple’s CEO. “From the recycled materials in our products, to the clean energy that powers our operations, our environmental work is integral to everything we make and to who we are. So we’ll keep pressing forward in the belief that great technology should be great for our users, and for the environment.”

“Our ambition to one day use 100 percent recycled and renewable materials in our products works hand in hand with Apple 2030: our goal to achieve carbon neutral products by 2030,” said Lisa Jackson, Apple’s vice president of Environment, Policy, and Social Initiatives. “We’re working toward both goals with urgency and advancing innovation across our entire industry in the process.”

Charting Progress to 2025

Apple has significantly expanded the use of 100 percent certified recycled cobalt over the past three years, making it possible to include in all Apple-designed batteries by 2025. In 2022, a quarter of all cobalt found in Apple products came from recycled material, up from 13 percent the previous year. Cobalt is a critical material in the batteries used in most consumer electronics, including Apple devices, enabling high energy density while also meeting Apple’s robust standards for longevity and safety. Apple-designed batteries found in iPhone, iPad, Apple Watch, MacBook, and many other products represent a significant majority of the company’s use of cobalt.

The company’s use of 100 percent certified recycled rare earth elements has greatly expanded in the last year as well, going from 45 percent in 2021 to 73 percent in 2022. Since first introducing recycled rare earths in the Taptic Engine of iPhone 11, Apple has expanded its use of the material across its devices, including in all magnets found in the latest iPhone, iPad, Apple Watch, MacBook, and Mac models. As magnets are by far Apple’s largest use of rare earths, the new 2025 target means nearly all rare earths in Apple products will soon be 100 percent recycled.

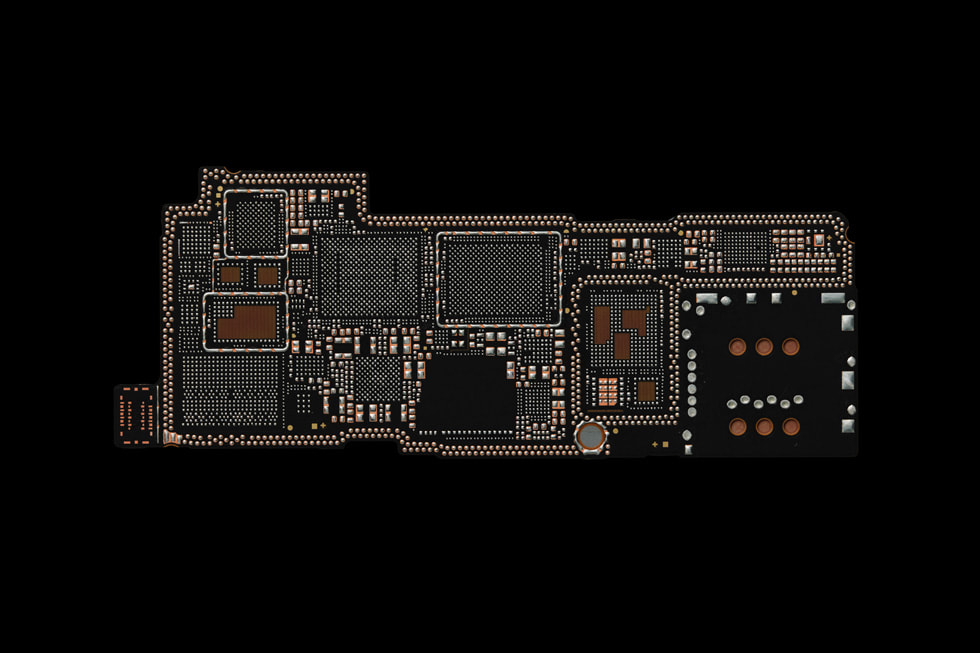

As part of the accelerated new timeline, all Apple-designed printed circuit boards will use 100 percent certified recycled gold plating by 2025. This includes rigid boards, such as the main logic board, and flexible boards, like those connecting to the cameras or buttons in iPhone. Since pioneering an exclusively recycled supply chain for gold in the plating of the main logic board for iPhone 13, Apple has extended the material’s use in additional components and products, including the wire of all cameras in the iPhone 14 lineup, and printed circuit boards of iPad, Apple Watch, AirPods Pro, MacBook Pro, Mac mini, and HomePod. Apple is also working to encourage broader adoption of recycled gold for non-custom components across the electronics industry.

By 2025, the company will use 100 percent certified recycled tin soldering on all Apple-designed printed rigid and flexible circuit boards. In recent years, Apple’s use of recycled tin has expanded to the solder of many flexible printed circuit boards across Apple products, with 38 percent of all tin used last year coming from recycled sources. The application of recycled tin across even more components is underway, and the company is engaging more suppliers in this effort.

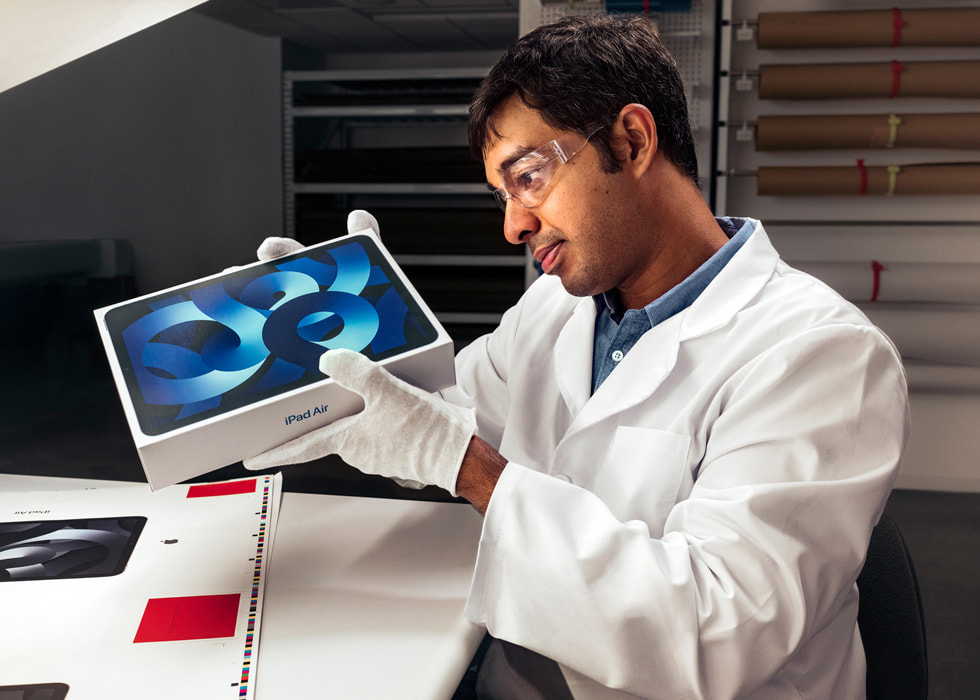

Innovation has also driven progress toward another of Apple’s 2025 commitments: to eliminate plastics from the company’s packaging. The development of fiber alternatives for packaging components like screen films, wraps, and foam cushioning has kept Apple on track toward this ambitious goal. To address the remaining 4 percent plastic in the company’s packaging footprint, Apple is innovating to replace labels, lamination, and other small uses. In the last year, Apple developed a custom printer to introduce digital printing directly onto the boxes of iPhone 14 and iPhone 14 Pro, eliminating the need for most labels. And a new overprint varnish found in iPad Air, iPad Pro, and Apple Watch Series 8 packaging replaces the polypropylene plastic lamination found on boxes and packaging components. The innovation helped avoid over 1,100 metric tons of plastic and over 2,400 metric tons of carbon dioxide.

Progress in Responsible Sourcing of Primary and Recycled Materials

As Apple reduces its reliance on newly mined minerals, it is also pursuing ways to directly support communities whose livelihoods depend on mining. The company is partnering with experts such as the Fund for Global Human Rights to provide support for frontline human rights and environmental defenders, including in the African Great Lakes region, as well as vocational education programs that enable members of local communities moving away from mining to build skills and pursue new opportunities.

Apple sources primary minerals responsibly and drives the highest level of human rights and environmental standards across its supply chain. Apple was the first electronics company to publish a list of cobalt and lithium refiners in its battery supply chain, with cobalt in 2016 and lithium in 2020. In 2017, the company mapped its supply chain for rare earths. And since 2015, every identified smelter and refiner for tin, tungsten, tantalum, and gold has participated in independent third-party audits.

In the transition to recycled and renewable content, Apple has prioritized 14 materials based on environment, human rights, and supply impact that together account for nearly 90 percent of the material shipped in Apple products: aluminum, cobalt, copper, glass, gold, lithium, paper, plastics, rare earth elements, steel, tantalum, tin, tungsten, and zinc.

In 2022, about 20 percent of all material shipped in Apple products came from recycled or renewable sources. This includes the first use of recycled copper foil in the main logic board of iPad (10th generation), the introduction of certified recycled steel in the battery tray of MacBook Air with the M2 chip, 100 percent recycled tungsten in the latest Apple Watch lineup, and the aluminum enclosures found in many Apple products, made with a 100 percent recycled aluminum alloy designed by Apple.

Innovating for the Future of Recycling

Apple’s work to pioneer new research and development for end-of-life disassembly and recycling has helped make this progress possible. Through extensive efforts including partnerships with leading research institutions and the Material Recovery Lab in Austin, Texas, Apple engineers and experts are developing innovative ways to give materials in Apple products new life, and helping inform design decisions that support disassembly and recovery.

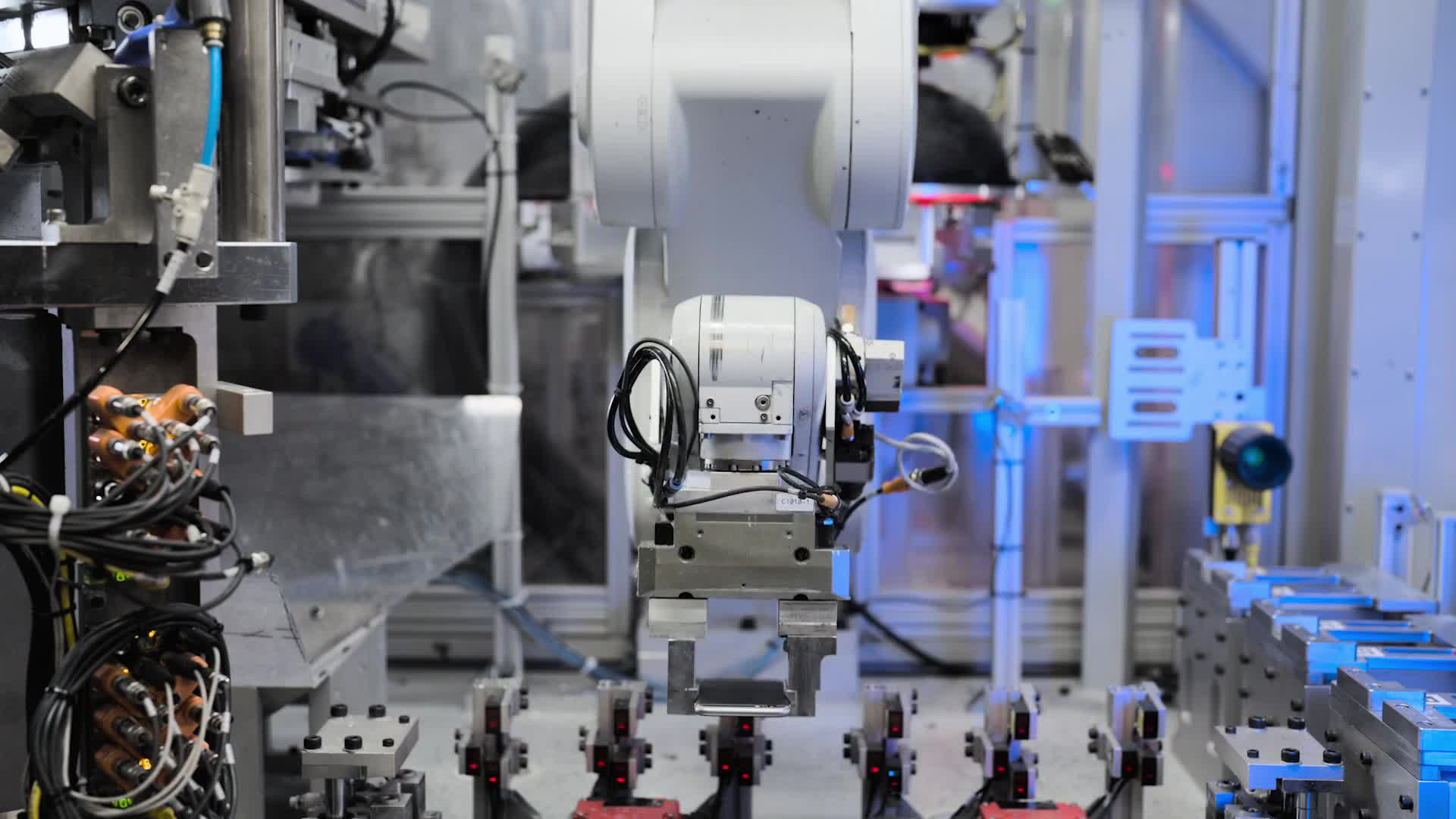

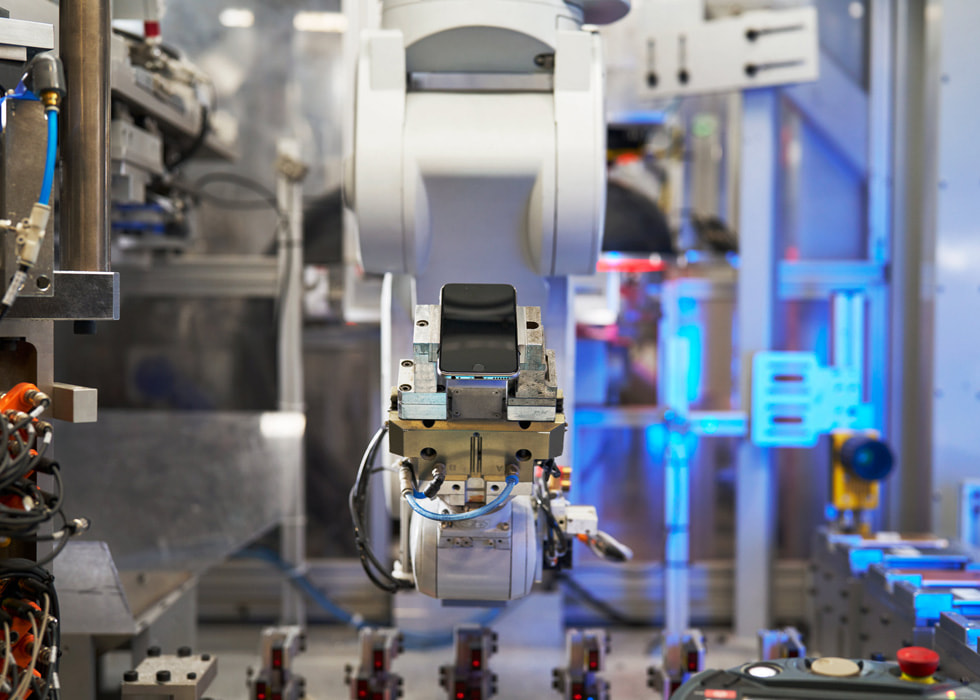

The company’s iPhone disassembly robot, Daisy, separates batteries from other components, and enables specialty recyclers to recover cobalt and other materials, including lithium. Since 2019, Apple estimates that more than 11,000 kilograms of cobalt have been recovered from batteries extracted by Daisy and then returned to the secondary market. Daisy also helps recover rare earth elements, which are largely lost through traditional electronics recycling processes.

Daisy is just one example of how Apple’s innovations in recycling and disassembly can drive industrywide change. The company’s Dave robot, now deployed with a recycling partner in China, can help further accelerate recovery of rare earth elements by disassembling Taptic Engines.

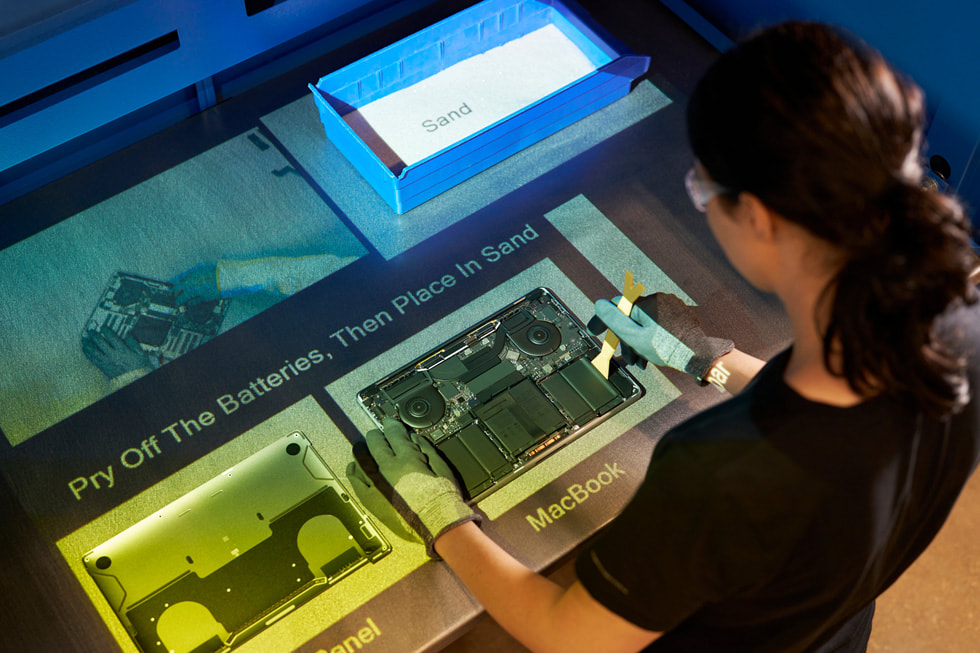

Apple has also begun deploying overhead projector-based augmented reality (AR) systems to recycling partners. The system guides the disassembly of devices including MacBook and iPad by projecting video imagery directly onto a work surface. The company publishes Apple Recycler Guides for global recyclers to maximize efficiency of material recovery while safeguarding human health and safety. As recycled and renewable materials can contribute to lowering each product’s carbon footprint, enhanced recovery is also bringing Apple closer to its ambitious goal to be carbon neutral across its entire supply chain and the life cycle of every product by 2030.

About Apple

Apple revolutionized personal technology with the introduction of the Macintosh in 1984. Today, Apple leads the world in innovation with iPhone, iPad, Mac, Apple Watch, and Apple TV. Apple’s five software platforms — iOS, iPadOS, macOS, watchOS, and tvOS — provide seamless experiences across all Apple devices and empower people with breakthrough services including the App Store, Apple Music, Apple Pay, and iCloud. Apple’s more than 100,000 employees are dedicated to making the best products on earth, and to leaving the world better than we found it.

- All cobalt content references are on a mass balance system basis.

Press Contacts

Sean Redding

Apple

[email protected]

(669) 218-2893

Apple Media Helpline

[email protected]

Originally published at Apple

Source: Cyberpogo

For enquiries, product placements, sponsorships, and collaborations, connect with us at [email protected]. We'd love to hear from you!

Our humans need coffee too! Your support is highly appreciated, thank you!