Today, manufacturers are advancing on their factory digitalization journey, betting on innovative technologies to strengthen competitiveness, deliver sustainable growth, and offer new services. Macroeconomic factors – such as high energy costs, increasing labor, and raw material shortages – drive the need for urgent operational optimizations and automation.Cloud capabilities have matured at an accelerated pace, giving manufacturers practical avenues to achieve these goals. Manufacturers are finding new ways to bring AI and machine learning (ML) to practical use cases, like predictive maintenance, anomaly detection, and asset utilization management. However, manufacturers struggle to adopt AI at scale due to challenges around data accessibility, infrastructure, and technology.

From our partners:

The journey to machine learning insights starts with accessible data

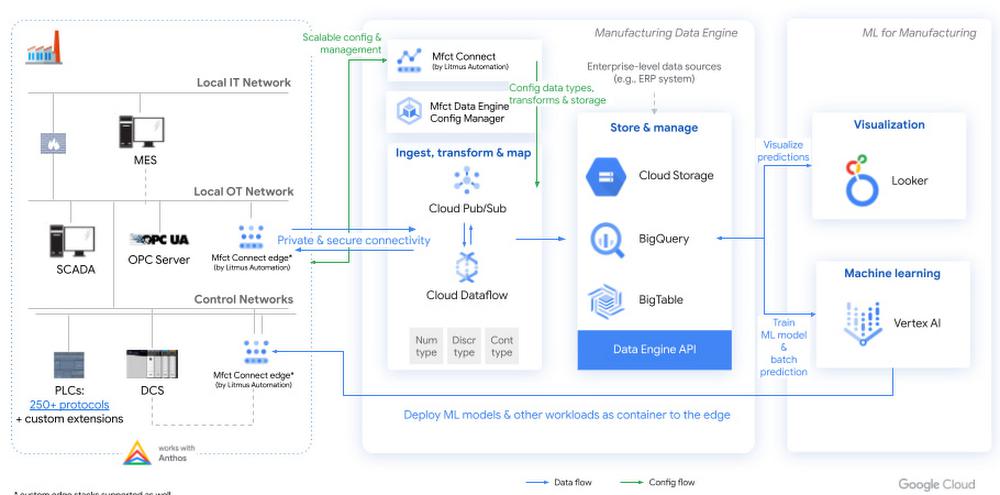

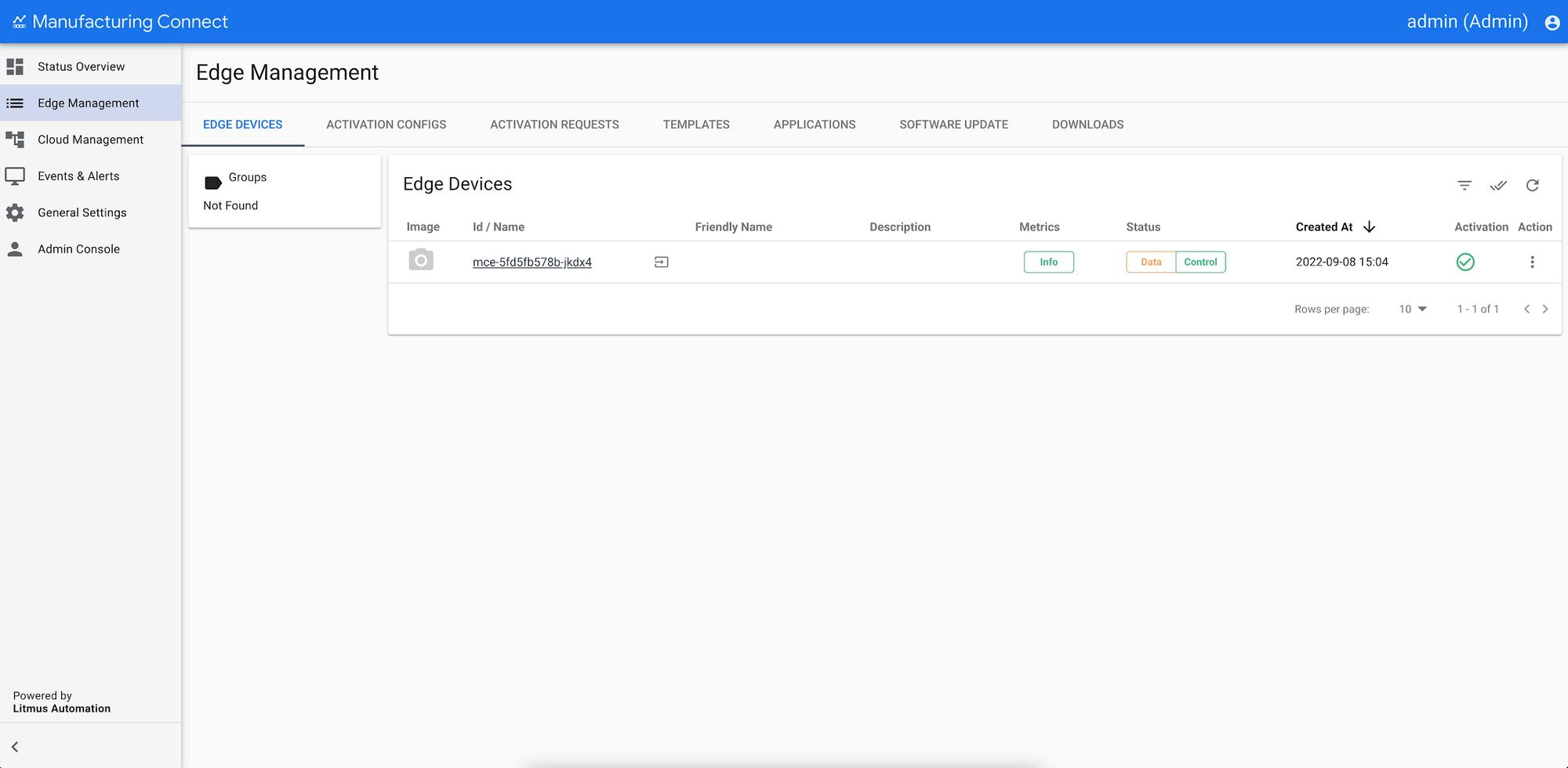

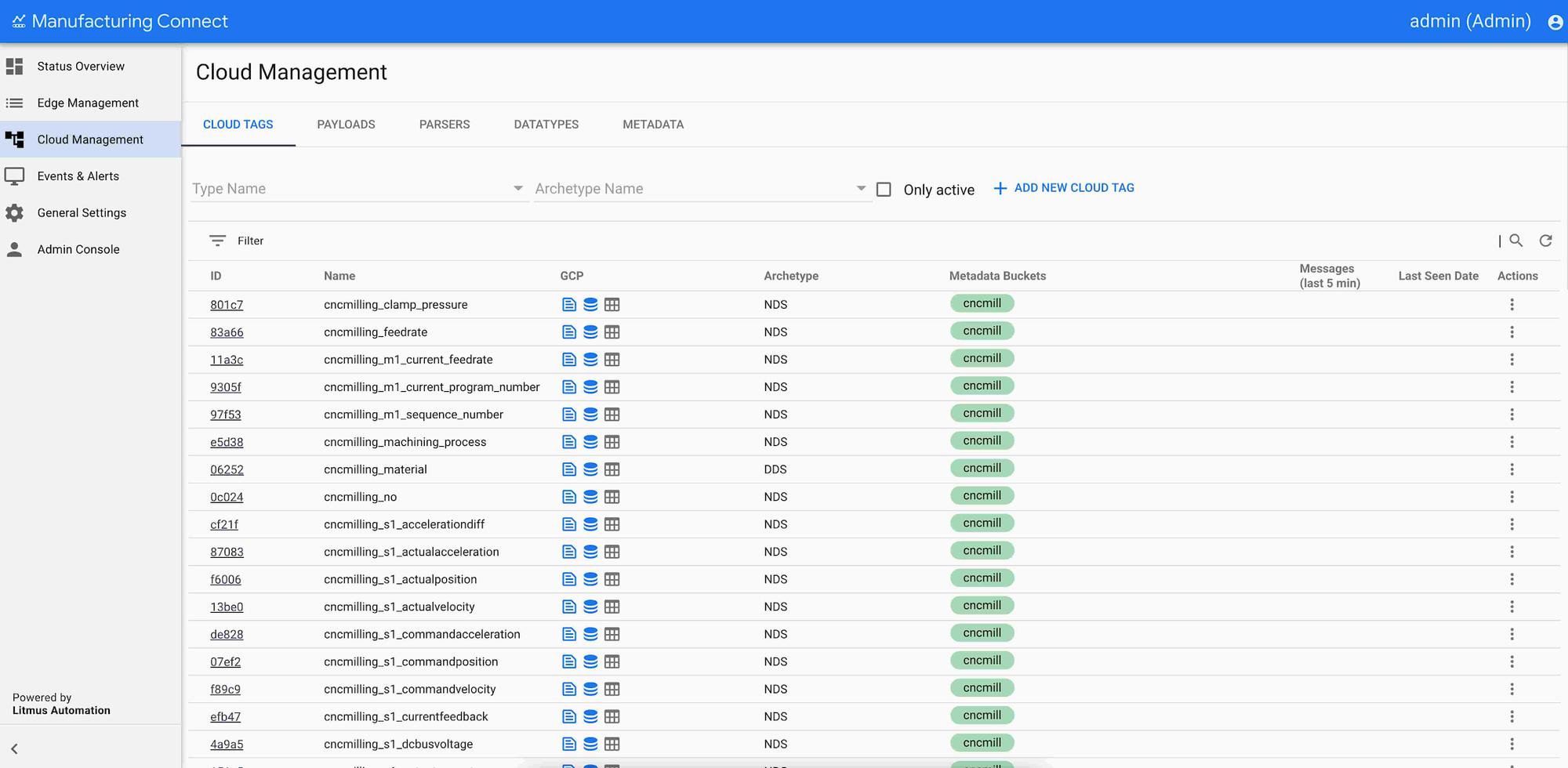

The first step to a successful machine learning project is to unify necessary data in a common repository. For this, we will use Manufacturing Connect, the factory edge platform co-developed with Litmus Automation, to connect to manufacturing assets and stream the asset telemetries to Pub/Sub.

After the telemetry messages are published to Pub/Sub, Dataflow will identify each message based on its structure and apply corresponding normalizations and transformations, which are preconfigured in Manufacturing Data Engine. Once the messages are processed, the messages will be routed to Cloud Storage, BigQuery, and/or Cloud BigTable based on user configuration.

Figure 1. High level architecture diagram of machine learning with Manufacturing Data Engine

A blueprint for classifying asset condition

The following scenario is based on a hypothetical company, Cymbal Materials. This company is a factitious discrete manufacturing company that runs 50+ factories in 10+ countries. 90% of Cymbal Materials manufacturing processes involve milling, which are accomplished using industrial computer numerical control (CNC) milling machines. Although their factories implement routine maintenance checklists, there are unplanned and unknown failures that happen occasionally. However, many of the Cymbal Materials factory workers lack the experience to identify and troubleshoot failures due to labor shortage and high turnover rate in their factories. Hence, Cymbal Materials is working with Google Cloud to build a machine learning model that can identify and analyze failures on top of Manufacturing Connect, Manufacturing Data Engine, and Vertex AI.

For the pilot, Cymbal Materials forms a team of manufacturing engineers and data scientists to evaluate the feasibility of solving the tool wear detection problem. To avoid compliance concern, the Cymbal Materials team chooses to start with a public tool wear detection dataset hosted on Kaggle. This dataset is collected from running machining experiments on 2″ x 2″ x 1.5″ wax blocks in a CNC milling machine. The dataset contains measurements from the 4 motors (X,Y, Z axes and spindle) and program values in the CNC machine, which maps well to the data that Cymbal Materials collects for their CNC milling machines.

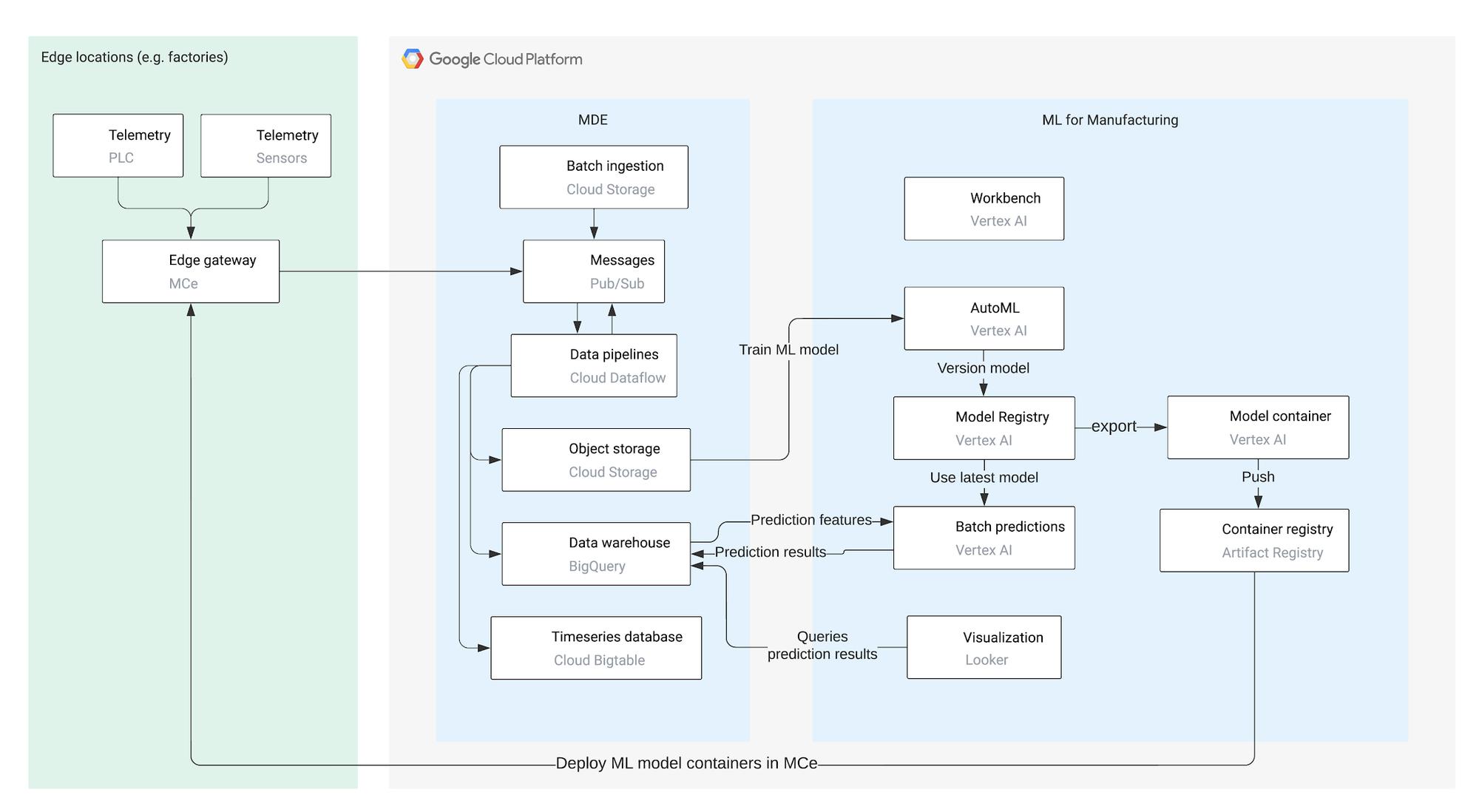

Figure 2. Architecture diagram of machine learning with Manufacturing Data Engine.

- Perform exploratory data analysis using Vertex AI Workbench

- Train machine learning models using Vertex AI AutoML

- Deploy machine learning models to perform batch prediction and export AutoML models for edge deployment

- Interpret predictions using Vertex Explainable AI

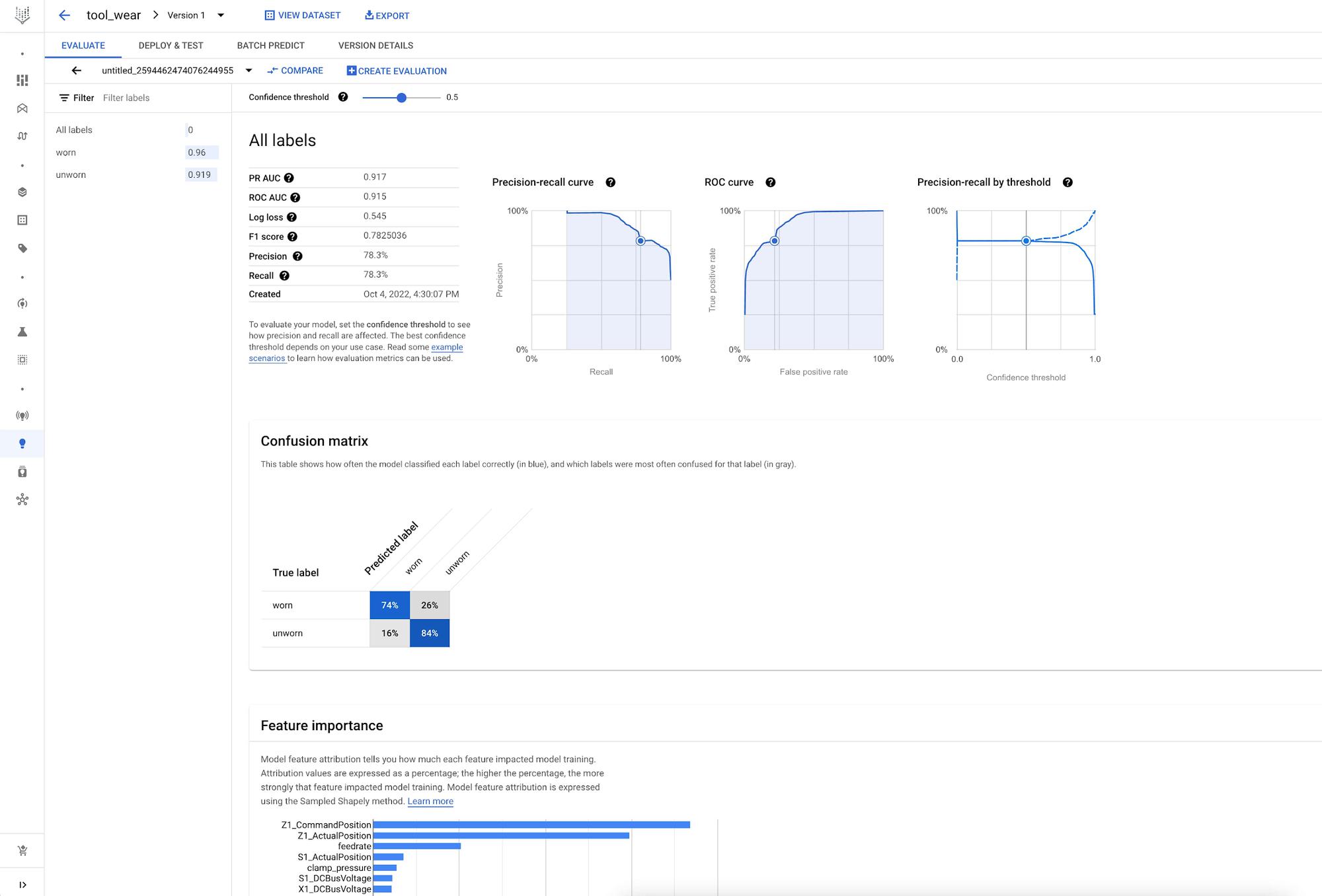

Figure 3. Vertex AI AutoML model performance

Figure 4. Manufacturing Connect user interface

- Normalize, transform, and contextualize real-time operational data with slowly changing metadata

- Batch ingest historical operational data and prediction results

- Route data dynamically to Cloud Storage, BigQuery, and/or Cloud BigTable

Figure 5. Manufacturing Data Engine configuration in Manufacturing Connect.

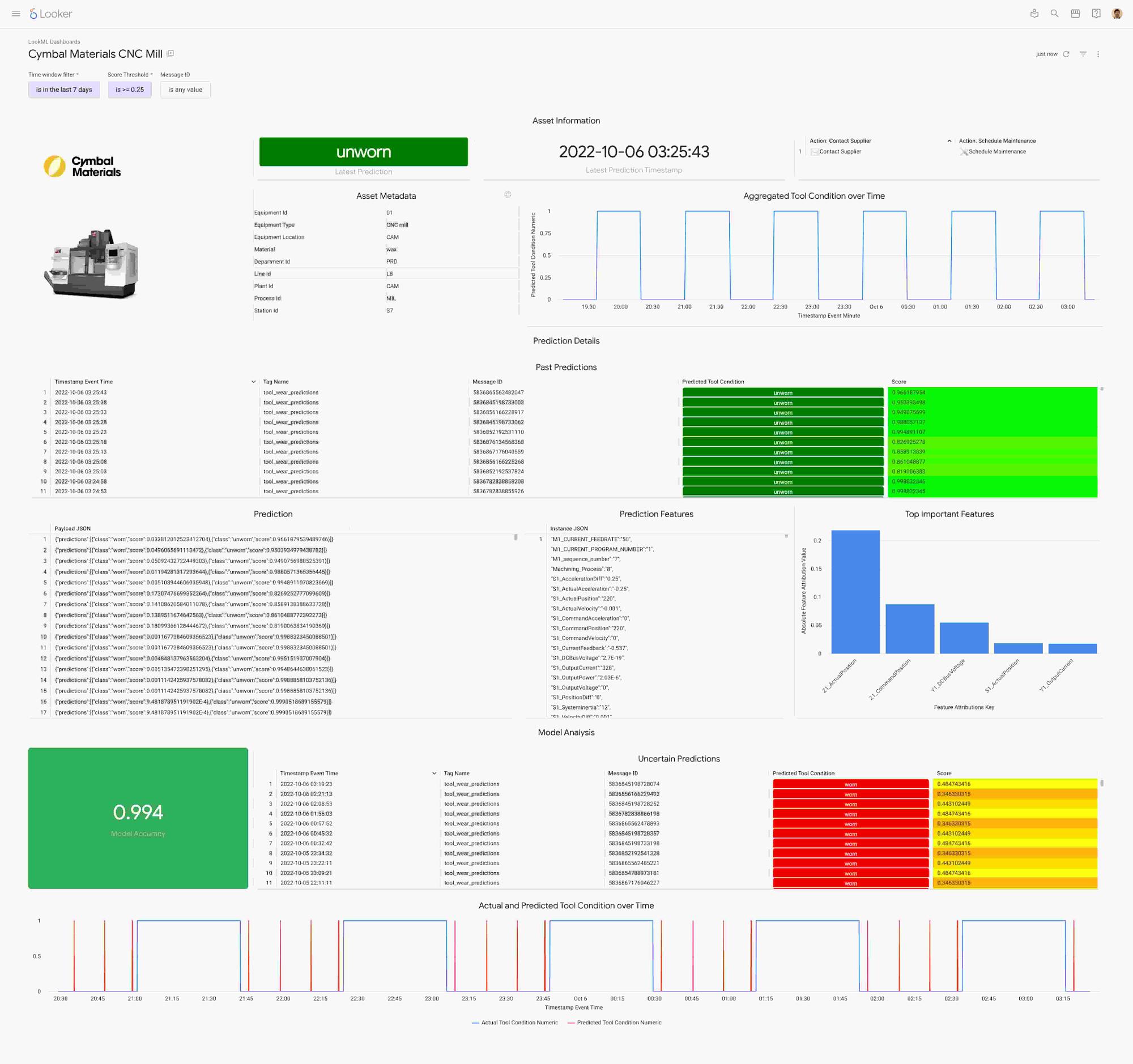

- Visualize the CNC milling machine actual and predicted tool conditions over time

- Explain the prediction results by summarizing the top attributing features

- Create alerts based on the predicted tool condition for their assets

- Take actions by contacting the supplier and/or scheduling maintenance for their assets

Figure 6. CNC mill wear prediction displayed in a Looker dashboard.

From edge to cloud, improving production efficiency for manufacturers

To support the entire factory digitalization value journey, manufacturers are looking for capabilities from simple visualizations to predictive ML models. Robust solutions, such as the one covered here, provide rapid paths for engineers to extract insight from their factory data.

Having a common data repository for manufacturing data, industry-leading machine learning platform, and versatile dashboard components accelerate manufacturer’s digital transformation.

This solution brings the best of Google Cloud’s data analytics and artificial intelligence capabilities in an industrial environment. Manufacturing Connect creates the link between industrial machinery and Manufacturing Data Engine, the cloud platform where the manufacturing data are processed, normalized, contextualized, and stored in a ready-to-consume format. Vertex AI can build, deploy, and scale machine learning models using data stored in the Manufacturing Data Engine. Vertex AI includes AutoML and Workbench for training models without code and training custom models with code-first experience respectively.

Learn more about how Google Cloud is transforming manufacturing to meet changing customer expectations at our Google Cloud Next Manufacturing playlist.

What’s next

- Introducing new Google Cloud manufacturing solutions: smart factories, smarter workers

- Manufacturing Data Engine | Solutions | Google Cloud

- GitHub – GoogleCloudPlatform/mfg-ml-examples

By: Ka Wo Fong (Industry Solutions Architect, Cloud Manufacturing Solutions, Google Cloud) and Charlie Sheridan (Global Technical Director, Manufacturing, Industrial & Transportation, Google Cloud)

Source: Google Cloud Blog

For enquiries, product placements, sponsorships, and collaborations, connect with us at [email protected]. We'd love to hear from you!

Our humans need coffee too! Your support is highly appreciated, thank you!