Powered by Vertex AI (Google Cloud’s platform for accelerating development and deployment of machine learning models into production), SAVI (Semi Automated Vision Inspection)1 is transforming surgical instrument identification and cataloging, leading to fewer canceled surgeries and easing pressure on surgery waitlists.

From our partners:

Eliminating time-consuming manual processes

Surgeons need a large number of specialist instruments and devices to complete complex, delicate procedures. Because each tray of these instruments can typically cost more than $350,000, and having every type of set on shelf at every surgical facility is not feasible, manufacturers generally loan them to hospitals for procedures, such as inserting one of the manufacturers’ implants into a patient’s knee. Once a procedure is complete, the hospital returns the instrument tray to the manufacturer for storage and re-distribution to other hospitals as needed.

Each time a hospital returns a tray, the manufacturer needs to check that each instrument is there, correctly placed, cleaned, and fit for the purpose of the next procedure. As each set may hold more than 400 instruments, completing this process manually is complex and time-consuming. While each tray is checked before and after surgery at the hospital, and again when it arrives and leaves the manufacturer’s facility, Max Kelsen finds that 5% of surgeries can still be affected by missing, broken or bent instruments. This has a severe downstream impact on private hospitals in particular, directly affecting patient safety and outcomes; in Australia, for example, around 60% of surgeries are performed in private hospitals.

Johnson & Johnson MedTech has 60,000 surgical trays across the Asia-Pacific, and loans these trays out about 100,000 times per month. The manufacturer approached Max Kelsen to help design and develop a solution to make the supply chain more efficient, and to give more visibility into asset movement. As a Google Cloud Partner specializing in applying machine learning at scale in healthcare contexts, Max Kelsen had the expertise and track record to meet Johnson & Johnson MedTech’s need for a globally scalable solution that was engineered for quality and performance.

The first step was to establish a baseline for the project by determining how long the manufacturer’s team took to process each tray, and to set an efficiency number. We then spent six months determining and evaluating how to deliver a robust, accurate solution that outperformed current manual and labor-intensive methods in processing instruments and trays, globally. Our work included extensive technical feasibility research involving a representative sample for the variety and complexity of sets, trays, and devices needed for different types of surgery, including orthopedics, spinal trauma, and maxillofacial groups.

Working with Google Cloud to accelerate and de-risk the project

This is a familiar problem that is industry-wide. The issue has been widely explored and tried with a number of technologies over several years without producing the scalability and performance results required to make this an appropriate and feasible solution. Google Cloud partnered with Max Kelsen to accelerate and de-risk this large and strategic project for a mutual customer.

Technical feasibility took four months, prior to a year-long production pilot of SAVl in a distribution center in Queensland that services over 100 hospitals. After obtaining enough real-world data and experience to validate that the solution was as scalable and as accurate as needed, an Asia-Pacific rollout of the system commenced. SAVI is now live across Johnson & Johnson MedTech’s operations in Australia, New Zealand, and Japan, garnering recognition with a JAISA excellence award.

Google Cloud machine learning is integral to SAVI. Google Cloud’s technologies were a big differentiator for Max Kelsen’s engineering team in delivering the breakthroughs needed at scale, and in production, to meet Johnson & Johnson MedTech’s needs.

Reducing checking and documentation time

Running SAVI in Google Cloud has reduced the time Johnson & Johnson MedTech needs to check and document inspections of these surgical instrument sets by over 40%. The application also delivers consistent measurable quality that is often hard to measure at scale when using manual processes. During the pandemic, the application enabled Johnson & Johnson MedTech to operate with a lower headcount for the same volume output, enabling the organization to quickly service a backlog of waiting list surgeries.

In addition, the automation delivered with SAVI has reduced the time required to bring technicians up to speed on quality control processes, from eight to 12 months down to just three months, enhancing productivity and performance while delivering a more robust workforce.

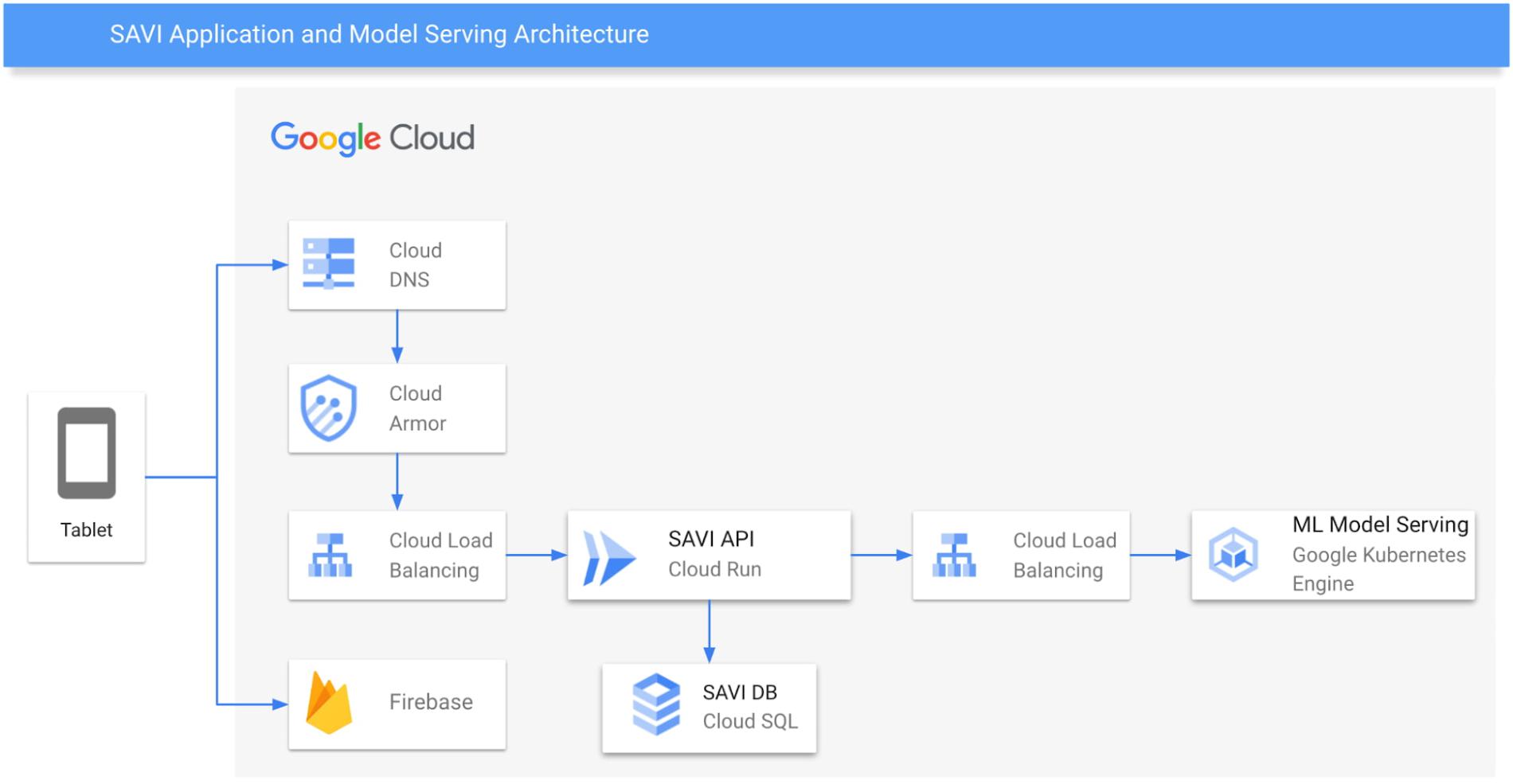

So how does SAVI work in a real-world context? SAVI is deployed via a tablet and a web-based application incorporates an API to photograph the medical device trays, as shown below. Max Kelsen captures the photograph and sends it to a range of different services, via an API endpoint hosted on Google Cloud:

- Image information is stored in Cloud Storage

- Data relating to the trays is stored in Cloud SQL for PostgreSQL

- APIs and web UI components run in CloudRun

- Analytics data is stored within BigQuery

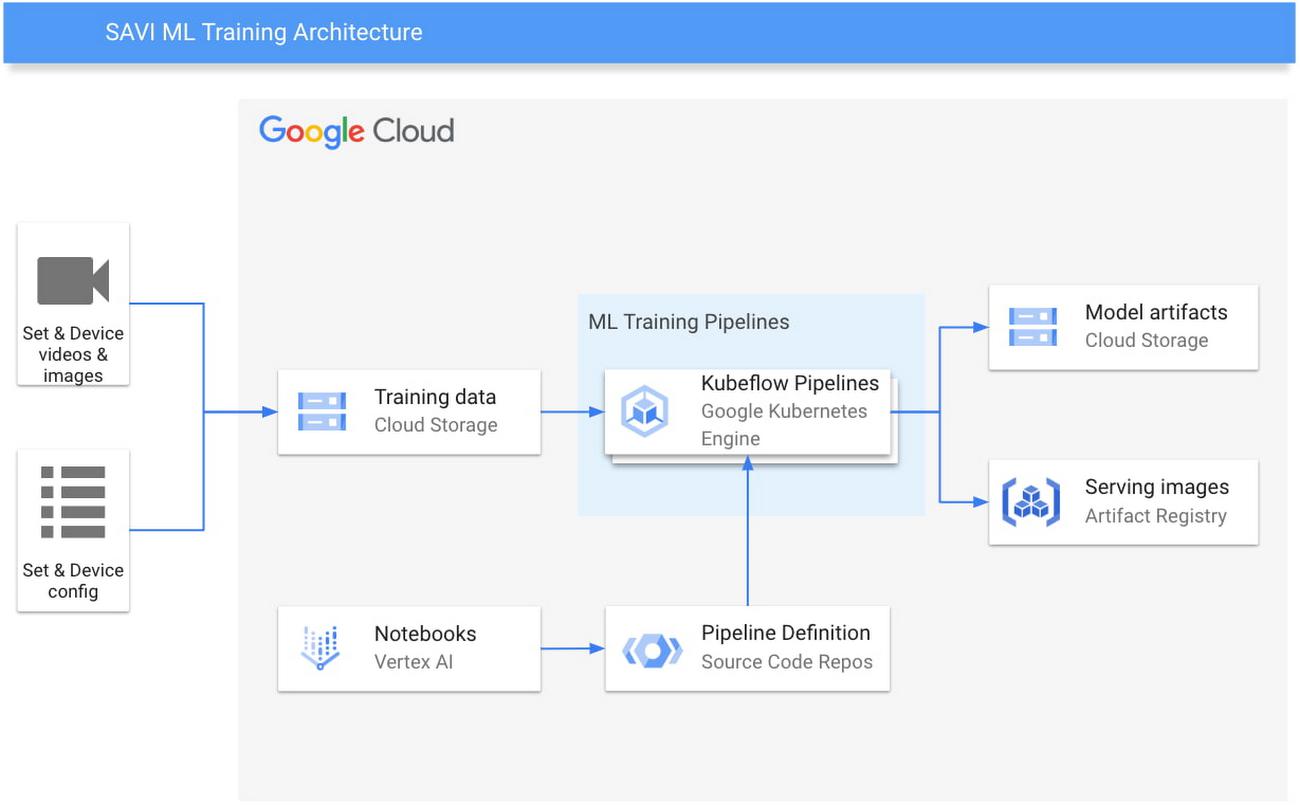

Once this tray and device onboarding stage is completed, the next step is to perform inferences from the images and data. By hosting online models with Kubeflow model serving on GKE, we enable a model to identify all the instruments in a tray at low latency.

1.Not to be confused with the usage of Visual Inspection Model (Assembly) available in Vertex AI Vision

By: Michael Blake (VP Engineering and Architecture, Max Kelsen) and Cameron Bean (FAIDH, Global Health Care and Life Sciences Lead)

Source: Google Cloud Blog

For enquiries, product placements, sponsorships, and collaborations, connect with us at [email protected]. We'd love to hear from you!

Our humans need coffee too! Your support is highly appreciated, thank you!